Steam Generators for Enhanced Oil Recovery

Overview

Steam Generators

Steam generators for recovering the highest possible percentage of Original Oil In Place (OOIP) is an urgent concern in today’s political environment — one for which you need the most advanced control system available. At ACES we’ve combined 50 years experience with control systems and 15 with steam generators, and applied them to the challenges of the Enhanced Oil Recovery (EOR) industry.

ACES is ISO 9001:2015 Certified in Design, Development, Manufacture, Installation, and Technical Support on a World-Wide basis for Steam Generation Technologies and Products for the Oilfield Industry.

With our ASME S, National Board Inspection Code, and NB-415 certifications we can build and refurbish Oilfield Steam Generators. Currently we have a new 27 MMBTU under construction, used 50 MMBTU in refurbishment (incl. new convection and control system), And a 30 MMBTU (NOS) recently unpacked from OEM crates and getting prepped for testing. The 30 MMBTU will be upgraded with new wiring and control system. The new Aces wiring system is designed to ease and encourage owner assembly and start up at arrival of its desired location. “Plug and Play”

ACES Services and OTSG Systems

Can Be Found Operating In the Following Countries

| Location | Machines | Size (Btu/hr) |

| Canada | 5 | 25 MM to 73 MM Twin Pass |

| USA | 6 | 10 MM to 85 MM Twin Pass |

| Mexico | 7 | 25 MM to 32.5 MM |

| Colombia | 3 | 25 MM to 50 MM |

| Venezuela | 4 | 25 MM to 32.5 MM |

| Egypt | 1 | 10 MM |

| Kuwait | 2 | 30 MM |

Introducing the FlexSteam Control System

Why FlexSteam Control System

Whether your generator is 5 or 50 years old, whether you’re outputting 5,000 or 100,000 pounds of steam per hour, we’ve designed a steam generator control system that automates the entire process and enables you to predict your steam discharge quality within very fine tolerances.

Standardized Yet Adaptable

With FlexSteam we’ve standardized our control system software to fit any sized generator — and yet there’s plenty of room for customization: Choose to burn natural gas, propane, oil or diesel fuel. Specify your generator size and other variables such as water flow and steam pressure. The FlexSteam Control System offers the quick installation and simple setup you need, while still giving you all the options you want.

Complete Automation

Some of our clients with older generators are amazed at the automation achieved when we install FlexSteam on their machines. “You mash the button and walk away,” said one happy customer, who was accustomed to fiddling with buttons and levers to keep his generators on track. “I can get in my truck and leave, and when I come back it’s still running.” This automation system also has options for emissions tracking and control.

Reduce Fuel Consumption, Increase ROI

It’s not uncommon for our customers to see a 20% increase in fuel-to-steam efficiency after installing FlexSteam. Thanks to higher steam quality, lower fuel costs, emissions control, automation, and ease of use, FlexSteam can pay for itself in as little as a year or two.

ACES Experts can provide Turnkey solutions to renovate the steam generator. All services performed in house or in the field by the ACES Team.

Areas of Expertise

- Control system engineering

- Remote system monitoring

- Control panel design and assembly

- Historical data collection

- PLC/PAC/HMI programming

- PLC conversions

- Field instrumentation

- Network architecture (LAN/WAN)

- Maintenance, upgrades, and modifications

- Variable frequency drives

Learn More

Generator Components Section 1

- Air Compressor

- Atomization; Air and Steam

- Burner

- Check Valve

- Combustion Blower

- Control Valves

- Convection Section

- Differential Pressure Transmitters

- Exhaust Stack

Generator Components Section 2

- Feedwater

- Flue Gas Recirculation (FGR)

- Fuel Gas Main Train

- Fuel Gas Pilot Train

- Fuel Oil Train

- Generator Cab

- Generator Steam and Vent Valves

- Orifice Plate

- Quality Sample Condenser

Generator Components Section 3

- Radiant Section

- Refractory

- Safety Relief Valves

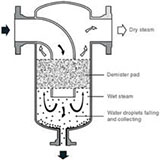

- Steam Separator

- Steam Traps

- TDS Meter

- Temperature Sensors

- Thermal Mass Meter

- Turbine Flow Meter

- U-Tube Manometer

- Water Softener