Generator Components Section 2

ACES Introduction to Generator Components

This section will provide an overview of functionality of components encountered throughout the steam generator. The information presented in this section is a general compilation of possible components on a steam generator. The appearance of many components depends on the style and setup of the generator.

Feedwater

The feedwater system includes all piping and equipment used with water before entering the convection section. Water enters the system and travels through an inlet stabilizer. Positive displacement pumps (like the feedwater pump) contain an inlet valve that continuously opens and closes, creating an acceleration and deceleration of fluid into the pump. The inlet stabilizer (pulsation dampener) minimizes pressure fluctuations created from this to stabilize the flow pattern at the pump inlet which helps to extend the service life of the pump. Inside the stabilizer is either a membrane or a bladder filled with pressurized gas. As turbulent water enters the stabilizer, the gas filled membrane or bladder absorbs the excess energy and returns the water to a more laminar flow pattern

Pulsation Dampener

Feedwater Pump

The water exits the inlet stabilizer and enters the feedwater pump. The feedwater pump can be either centrifugal or positive displacement, but positive displacement is the most common for steam generators since the water flow rate is directly related to the RPM of the pump allowing for easy flow rate calibration. When a centrifugal pump is used, an extra control valve is needed to control the flow rate. A centrifugal pump creates pressure from the flow rate; the higher the flow rate the higher the pressure. Do to this, to maintain a constant pressure but decrease the flow rate downstream of the pump, a secondary pipe is split off of the main line after the discharge dampener. This pipe recycles water back to the suction side of the pump. How much water is cycled back is controlled by the feedwater pump bypass control valve. Attached to the pump is a pressure safety relief valve. This valve connects the discharge of the pump to the pump suction in order to prevent over pressurization from occurring.

Feedwater Pump and Safety Valve

Feedwater Pump Belt and Sheaves

The feedwater pump belt and sheaves connect the feedwater motor to the pump. The smaller sheave is connected to the motor shaft and the larger sheave (typically 4 times larger) to the pump shaft. The sheaves are connected to each other by rubber v-belts. The motor speed is controlled by a VFD and as the motor spins it rotates the sheaves which in turn increases or decreases the pump speed. The number of belts (typically 4-6) and the required sheave size depend on the horsepower of the motor and the size of the pump. The sheaves and belts will be surrounded by a metal belt guard to prevent objects from coming in contact with the system while it is running. There will be a hinged door or a cutout over the center of the pump sheave, and possibly also the motor sheave, in order to measure the crankshaft speed. The crankshaft speed of the pump sheave is necessary for calibrating the feedwater flow rate.

Belt and Sheaves

Feedwater Pump Oil Level Switch

The feedwater pump oil level switch monitors the oil level in the oil reservoir. The oil reservoir is a small storage tank for the lube oil used by the feedwater pump. As the oil level in the reservoir decreases, the float inside the level switch goes down. Once the level reaches the low limit set point, the circuit is completed and an alarm is triggered that shuts the steam generator off. This oil is used to lubricate the feedwater pump internals. If the oil were to run out, the pistons would create a large amount of friction against the shafts and any gears or bearings inside the pump could wear away which would all ruin the feedwater pump. The switch can be manually tested to ensure it is working correctly by turning the needle, using the black knob on a Murphy, counterclockwise until it contacts the bottom plate or by pressing down the test knob on a Kenco style switch.

Pump Oil Level Switch and Reservoir

Feedwater Pump Oil Pressure Switch

Lube oil is an integral part to the feedwater pump. It keeps all the moving parts oiled and extends the life of the pump. Two main types of oil methods are used for oiling the pump. The first one is a mechanical method that is commonly called splash lubrication. A rotating dipper is attached to the pump crankshaft. Each time it rotates it passes through an oil filled trough where it picks up oil and splashes it on the necessary parts. However, this is not a precise method and does not work as well for larger pumps. On larger pumps, some parts may not get enough oil using splash lubrication. The second method is pressure lubrication. A lube oil pump is installed external to the feedwater pump. This oil pump is then used to distribute the oil directly to key areas of the pump in order to more effectively lubricate it. When a lube oil pump is installed, a feedwater pump oil pressure switch may also be installed. This pressure switch ensures that the lube oil pump pressure is not too high or too low.

Feedwater Pump Vibration Switch

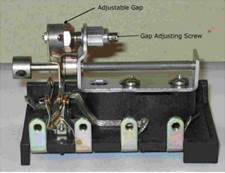

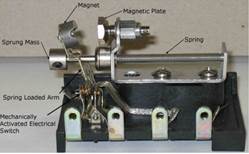

The feedwater pump vibration switch is used to sense vibration levels of the pump and shut down the generator if the pump is vibrating too much, which can cause damage to the pump. The vibration switch consists of a magnet mounted on a spring-loaded lever arm that is attached to mechanically activated electrical switch contacts. Above the magnet is an adjustable magnetic plate. The switch is held in place by the magnetic force between the magnet and the plate, which overcomes the force in the spring-loaded arm. The gap between these two pieces can be manually adjusted using the set screw on the top exterior side of the switch. Turning the set screw to “More Sensitive” increases the gap and turning it to “Less Sensitive” decreases the gap.

When vibration occurs, the magnet on the spring-loaded arm generates inertial forces that oppose the magnetic force holding the switch closed. Once the vibration generates an inertial force greater than the magnetic force, the switch trips and will remain tripped until reset. To reset the switch, press the pushbutton on the bottom side of the switch (opposite side of the set screw) this will manually push the magnet back into place with the magnetic plate. The vibration switch can be tested to ensure it is functioning properly by hitting the exterior of the switch with a hand or tool to make sure it trips.

Pump Vibration Switch

Set Switch

Pump Vibration Switch: Tripped Switch

Discharge Dampener

Upon exiting the feedwater pump, the water travels through a discharge pulsation dampener. This dampener works in the same manner as the inlet stabilizer but is built for high pressures and helps to maintain the structure of the piping after the pump rather than the pump itself. For very high-pressure systems, a pressure vessel dampener, also called a “zero maintenance” dampener, may be used instead. These are spherical dampeners that have no moving parts. This style of dampener causes the flow inside to spin which creates a smoothing effect that dampens surges from the amplified source. It can also partially rely on the compressibility of the fluid passing through it to absorb pressure fluctuations.

Zero Maintenance Pulsation Dampener

Shutoff and Check Valve

After leaving the discharge dampener, the water travels through the feedwater manual shutoff valve and check valve. The manual shutoff valve is used to isolate the upstream side of the feedwater line for maintenance purposes while still keeping the downstream side pressurized. The check valve prevents water from flowing back into the pump when the pump shuts down. See Check Valve for more information on check valves.

Feedwater Shutoff and Check Valves

Feedwater Pre-Heater

After leaving the check valve, the water travels through the pre-heater. The pre-heater heats the water to an acceptable temperature before it enters the convection section by using part of the water that exits the convection section. If the temperature entering the convection is too low it can cause condensation to form on the finned tubes which can rust the fins and inhibit heat transfer. At the exit of the convection section are two balance valves, however, some generators may only have one valve. These valves are used to divert the correct amount of hot water through the pre-heater in order to raise the temperature of the inlet water.

Feedwater Pre-heater

Flue Gas Recirculation (FGR)

FGR takes gas exiting the exhaust stack and circulates it back to the front of the generator where it is mixed with incoming combustion air. The mixture then passes through the burner for combustion. FGR is used for lowering NOx emissions in two ways. Firstly, mixing flue gas with combustion air lowers the oxygen content of the mixture which hinders the formation of NOx components since there is not an abundance of O2 present. Secondly, flue gas is mostly CO2 and inert N2. Adding these back into the combustion process lowers the peak flame temperature. Since NOx components are rapidly formed at high temperatures, lowering the flame temperature greatly reduces the formation of them.

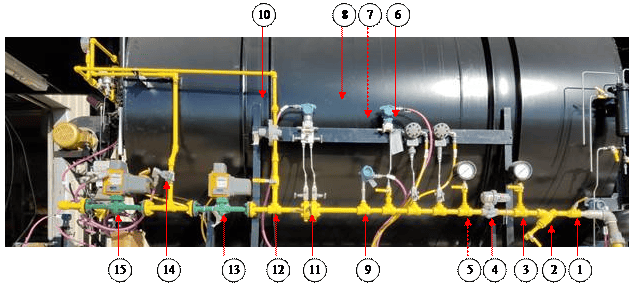

Fuel Gas Main Train

- Main Shut Off Valve

- Y-Strainer

- Upstream Regulator Pressure Gauge

- Pressure Regulator

- Downstream Regulator Pressure Gauge

- High Pressure Switch

- Low Pressure Switch

- Pressure Transmitter

- Temperature Transmitter

- Differential Pressure Transmitter

- Orifice Plate

- Pilot Line Diversion

- Block Valve

- Vent Valve

- Safety Valve

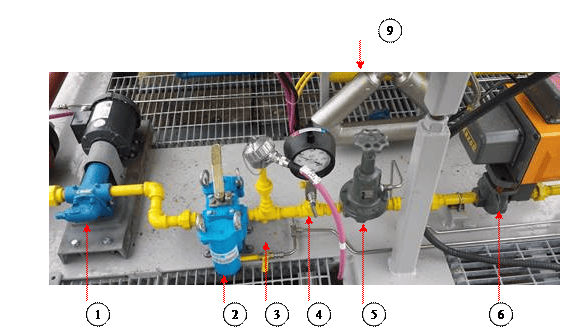

Fuel Gas Main Train

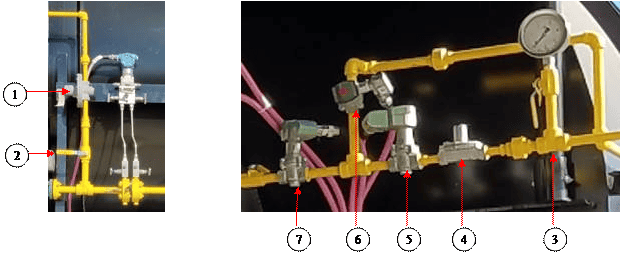

The fuel gas train includes all components between the burner and where the gas line attaches to the generator skid. All gas line piping should be painted yellow. Starting from where the gas line is attached; there will be a manual valve, typically a ball valve, which is used to shut off all gas to the gas line. After initial setup of the generator, this valve is typically only closed if maintenance needs to be done on the gas train.

The gas will pass through the main shutoff valve and enter a strainer. The incoming gas line may be filled with debris such as sediment, rust, or pipe scale which can be damaging to the downstream components. A y-strainer (named because of its shape) is used to mechanically remove small solids from the incoming gas. Inside the strainer is a cylindrical metal mesh screen tube. The gas enters the strainer, passes through the screen, and exits through the other side. Any debris in the gas is trapped by the screen tube and settles to the bottom of the Y arm. The bottom of the Y arm contains a removable side which is necessary for disassembling the strainer to clean out the screen. However, most y-strainers will have a blow down attachment which is a short pipe and valve threaded onto the removable side. Opening this valve while the gas line is pressurized will blow out any of the debris without having to shut down the generator.

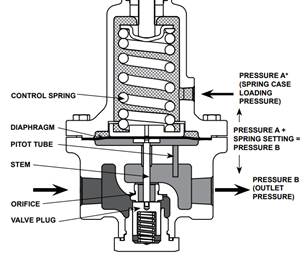

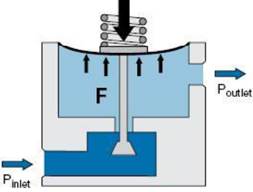

Upon leaving the strainer, the gas will enter the main regulator, which is used to reduce the gas pressure to the lower pressure needed for downstream service (typically 30-45 PSI). The size of the regulator depends on the flow rate of gas and the upstream gas pressure. A regulator is made up of three parts: restricting element, loading element, and measuring element. The restricting element is a valve that can provide a variable restriction to the flow. The loading element is a part that can apply the needed force to the restricting element and is typically a spring. The measuring element determines when the inlet flow is equal to the outlet flow and is typically a diaphragm.

Feedwater Pump and Safety Valve

Regulators come in both single and double stages. For a single stage regulator, gas enters the regulator and flows through the opening above the valve plug. As the pressure in the body of the regulator increases, the upward force exerted on diaphragm increases which compresses the top spring and raises the valve plug. This limits the flow allowed into the body thus reducing the pressure. Turning the set screw clockwise would increase the control spring tension and increase the maximum pressure allowed in the body. Turning the set screw counterclockwise would have the opposite effect and lower the allowed pressure.

Single Stage Regulator

A double stage regulator is essentially two single stage regulators put together. Gas enters the first chamber (pilot) which is controlled by a factory set screw that cannot be changed. This works as an initial pressure reducer. The gas then travels into the secondary chamber which can by varied using the operator set screw. Double stage regulators are used when the outlet pressure needs to remain constant for a long time. A single stage regulator will increase/ decrease the outlet pressure if the inlet pressure raises/drops which means that it needs to be reset manually, whereas a double stage regulator will be able to maintain a constant outlet pressure regardless of fluctuations at the inlet.

After leaving the regulator, the gas will pass through a pressure gauge, low pressure switch, high pressure switch, pressure transmitter, temperature transmitter, and differential pressure transmitter and orifice plate. Each unit may be slightly different as there is not a standard required configuration, but each generator should have each of these. The pressure gauge is typically right after the regulator since there is no visual gauge on gas regulators that tells the actual gas pressure.

The high- and low-pressure switches should be set to within the limits of the downstream equipment. Sometimes these two switches are contained within a dual high/low switch instead of two separate switches. The low-pressure switch indicates problems upstream of the switch. This could be something like a closed valve or clogged strainer. The high-pressure switch protects the downstream equipment from over pressurization. A valve diaphragm can burst if the valve receives a pressure higher than what it is rated for. If the burner receives gas at too high a pressure, it can overheat or ruin some of the internal components.

The pressure, temperature, and differential pressure transmitters are all necessary components for measuring the gas flow. Without all three of these, the PLC would not have a reference for flow and could not correctly control the fuel control valve. However, a fuel gas flow meter can be installed instead of the differential pressure transmitter and orifice plate. In this case, the flow is measured directly with the device instead of being calculated so the DTP, PT, and TT are not necessary.

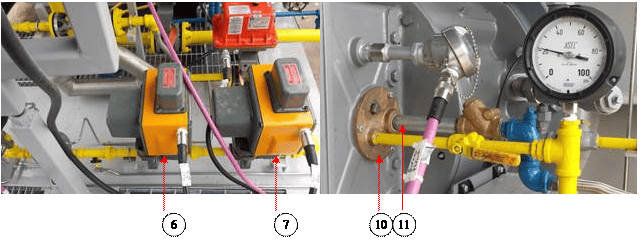

After the DPT or flow meter, the gas will split off in two directions. One line will continue as the main fuel line and the other will reduce to a smaller pilot line. The pilot line is covered in Fuel Gas Pilot Train. For the main line, the gas will pass through the block and safety valves. These are both normally closed valves that work in conjunction with the flame safeguard. They will stay closed until the main flame is called to light, at which point both will open and gas will pass through to the fuel control valve and burner. If the flame goes out or a shutdown alarm occurs, these valves will slam shut.

Double Stage Regulator

These two valves are used to prevent gas from entering the burner when there is no flame. Without these, the flame could go out and the radiant section would fill with gas which would create an explosion hazard upon relighting the burner. The safety valve is used as a backup in case the block valve fails. In between these two valves will be a vent line with a valve on it. The vent valve is a normally open solenoid that is used to send any gas in between the block and safety valve to atmosphere while they are closed. After the gas leaves the safety valve, it enters the fuel flow control valve and lastly passes through to the bottom of the burner.

Fuel Flow Control Valve

Fuel Gas Pilot Train

The pilot fuel train splits from the main fuel train between the differential pressure transmitter (gas flow meter) and the main block valve. The pilot line is easily distinguished from the main line by the reduction in pipe size (typically 2” down to ½”). The gas will enter the pilot high stage regulator where the pressure will be reduced to the acceptable range for the low stage regulator. The gas will then pass through a pressure gauge, the pilot low stage regulator, and enter the pilot block valve. The safety system used for the main gas line is also applied to the pilot line. This includes a block valve, safety valve, and a vent valve in-between the two. However, all three valves are simply solenoids due to the low flow rate of gas passing through rather than large shutoff valves like the main line.

Upon exiting the safety valve, the gas will typically pass by a pressure gauge and then enter the pilot premixing tube to the burner. The premixing tube has an inlet for the pilot gas and air supply. The pilot air supply is typically a tube or pipe that draws in air from the combustion air supply. The gas/ air mixture then passes by the spark ignitor where it is ignited and sent through the pilot flame tube and flame extender into the burner throat. The flame extender will stick out through one of the burner fuel ports on the fuel distribution ring.

Fuel Flow Control Valve

- Manual Shutoff Valve

- High Stage Regulator

- Upstream Pressure Gauge

- Low Stage Regulator

- Block Valve

- Vent Valve

- Safety Valve

- Downstream Pressure Gauge

- Gas Inlet to Mixing Tube

- Air Inlet to Mixing Tube

- Spark Ignitor

- Flame Extender

Fuel Oil Train

Optional:

- Heavy Oil Electric Heater

- Heavy Oil Steam Heater

- Fuel Oil Transfer Pump

- Fuel Oil High Pressure Switch

- Fuel Oil Low Pressure Switch

- Burner Feed pump

- Duplex Strainer

- Temperature Transmitter (Optional)

- Pressure Gauge

- Pressure Regulator

- Block Valve

- Safety Valve

- Flow Control Valve

- Coriolis Flow Meter

- Oil Inlet to Burner

- Atomization Air/Steam Inlet to Burner

Fuel Oil Train

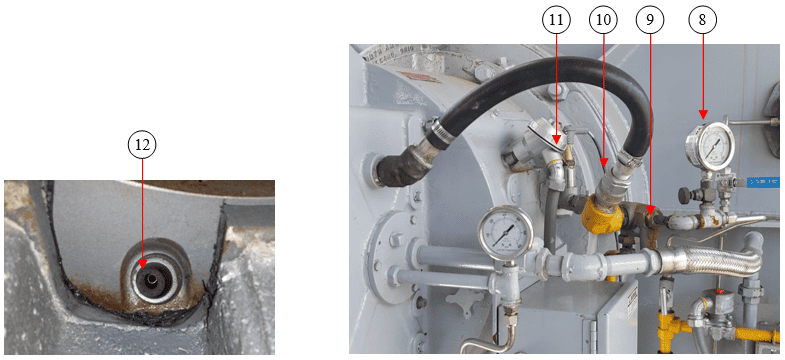

The fuel oil train includes all components between the burner and where the oil line attaches to the generator skid. However, depending on the type of oil and the climate, an oil heater and transfer pump may be located away from the generator. The oil heater decreases the viscosity of the oil allowing it to flow easier, and the transfer pump moves the oil from the heater to the oil inlet on the steam generator skid. The oil heater can be either fully electric or maybe both electric and steam operated. For an electric and steam heater, the heat will initially be supplied electrically and then will switch over to steam once the generator starts producing quality steam.

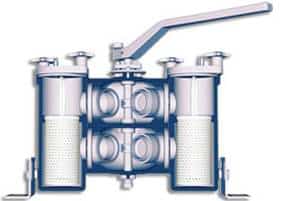

As with the gas train, the fuel oil train begins with a manual shutoff valve (typically a ball valve). The oil then passes through the burner feed pump which pressurizes the oil and sends it through a duplex basket strainer. Each side of the strainer has a mesh basket that catches any debris and allows the oil to flow through. The handle on the top of the strainer diverts the flow of oil to a single side, which allows the strainer to be cleaned without shutting off the oil. The bottom of each side will have a small valve that can be used to drain out any remaining oil from a side when it needs to be cleaned. The strainer can be cleaned by diverting the flow to the opposite side, opening the drain valve, removing the top on the side to be cleaned, and taking out the basket.

After leaving the strainer, the oil will pass through a temperature transmitter, pressure gauge or transmitter, pressure regulator, and possibly a high and/or low-pressure switch. The temperature and pressure transmitters are not mandatory components as the flow of oil is not a calculation based on these values like water and gas flow are. The regulator is used to maintain back pressure and reduce the oil pressure to the requirements for the burner. The oil then passes through the block valve, safety valve, control valve, and enters the Coriolis flow meter. Unlike the gas line, the oil train will not have a vent line and valve in-between the block and safety valves. Upon leaving the flow meter, the oil will enter the burner through a small plate that also contains the inlet for the air/steam atomization piping. Oil piping will most commonly be painted yellow, but may also be red.

Duplex Basket Strainer

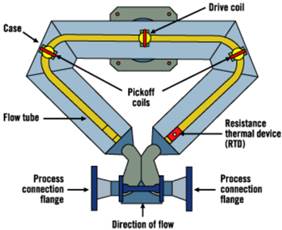

A Coriolis flow meter measures the mass flow of a fluid or gas by using the principles of the Coriolis Effect. The Coriolis Effect refers to the apparent effect on the motion of an object passing over a rotating frame of reference when viewed from the perspective of the point of origin of that moving object. An example of this effect can be modeled by looking at throwing a ball from the North Pole to the Equator. Although the ball travels in a straight line, to the perspective of the thrower the projected path of ball appears to curve due to the rotation of the Earth.

Coriolis Flow Meter

Fuel Flow Control Valve

Instead of having a rotating frame of reference, Coriolis meters work on the principle that the inertia created by fluid flowing through an oscillating tube causes the tube to twist in proportion to the mass flow rate. Inside the Coriolis meter are two tubes. These tubes have a magnetic coil that causes them to vibrate and bend in opposition to each other. Sensors made up of a magnet and coil assembly are mounted on the inlet and outlet of each tube. The magnets create a magnetic field and when the coils move through the field, they create a voltage in the form of a sine wave. When there is no mass flow, the motion of the two tubes is symmetrical. When there is mass flow, the two vibrations are out of sync. The two vibrations are shifted in phase with respect to each other and the degree of phase-shift is a measure of the amount of mass that is flowing through the tubes.

Fuel Flow Control Valve

Generator Cab

Includes:

- Generator Alarm Beacon

- Generator Cab Light Switch

- Generator Shutdown Beacon

The steam generator cab is the area under the canopy which includes the burner, main control panel, feedwater pump and ancillary equipment, and feedwater motor. Some units may also have air compressors in this location. Steam generators that are outside or inside of a building without lighting may have cab lights. These are lights that are located on the underside of the canopy which are used to illuminate the cab area. There will be a cab light switch near the control panel if lights are present. Some generators may also contain a shutdown or alarm beacon. Both will be loud horns and may also include a colored or flashing light. The shutdown beacon will sound whenever the generator is tripped by a shutdown alarm and the alarm beacon will sound whenever a non-shutdown alarm occurs.

Cab and Lights

Generator Steam and Vent Valves

Before steam enters the well, it will pass through the generator pressure control valve, steam manual valve, and a check valve. The steam manual valve is used to isolate the generator from the well. The vent valve is used during start up and shut down to divert low quality steam or water away from the well. This valve can either be a manual valve or an automatic control valve. When a manual valve is used, an operator will need to slowly close the vent valve once quality is reached. When an automatic control valve is used, the valve will automatically close itself once quality is reached.

Manual Valve

Vent Valve

Orifice Plate

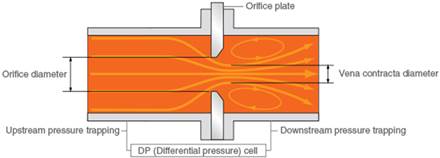

Orifice plates are thin metal plates with a machined circular and concentric bore, a sharp edge on the upstream side, and a beveled edge on the downstream side. The circular portion is wedged between two orifice flanges, each of which contain a flange tap for the DPT and is used for measuring the flow rate of a fluid passing through it based on Bernoulli’s equation. Bernoulli’s equation states that the pressure drop across a constriction is proportional to the square of the flow rate. To preserve the pipe size, an orifice plate is used to constrict the flow and provide a pressure differential. As a fluid flows through the orifice constriction, it is forced to converge which increases its velocity and decreases the downstream pressure. The location of maximum velocity and minimum pressure is known as the vena contracta. After that point the fluid expands, the velocity falls, and the pressure increases.

Each orifice plate will have one beveled edge which must be pointing downstream when installed. Installing a plate backwards can create significant error (12-17%) in the flow rate calculation resulting in understated volumes. The amount of beveling required on plates of the same thickness decreases as the pipe diameter increases. This means that smaller diameter pipe sizes like the ones used for water and gas on a steam generator are more susceptible to larger errors when an orifice plate is installed incorrectly. A backwards installed orifice plate records a smaller differential pressure because it takes less energy to push a gas through a hole with a beveled edge than one with a square edge (no bevel).

Orifice Plate

Quality Sample Condenser

The quality sample condenser is used to cool a portion of the water exiting the steam separator in order to take a TDS meter reading. This reading is used in conjunction with a TDS reading of a sample of feedwater to estimate the current quality that is being produced and make any calibration adjustments if necessary. The sample condenser will typically consist of a vessel which will fill with cool feedwater. This vessel will have a coiled tube inside which will have the hot water from the steam separator running through it.

Quality Sample Condensor

Learn More

Generator Components Section 1

- Air Compressor

- Atomization; Air and Steam

- Burner

- Check Valve

- Combustion Blower

- Control Valves

- Convection Section

- Differential Pressure Transmitters

- Exhaust Stack

Generator Components Section 2

- Feedwater

- Flue Gas Recirculation (FGR)

- Fuel Gas Main Train

- Fuel Gas Pilot Train

- Fuel Oil Train

- Generator Cab

- Generator Steam and Vent Valves

- Orifice Plate

- Quality Sample Condenser

Generator Components Section 3

- Radiant Section

- Refractory

- Safety Relief Valves

- Steam Separator

- Steam Traps

- TDS Meter

- Temperature Sensors

- Thermal Mass Meter

- Turbine Flow Meter

- U-Tube Manometer

- Water Softener